帕金斯2806柴油發(fā)電機(jī)ECM接線原理圖說(shuō)明

帕金斯2806柴油發(fā)電機(jī)ECM接線原理圖說(shuō)明

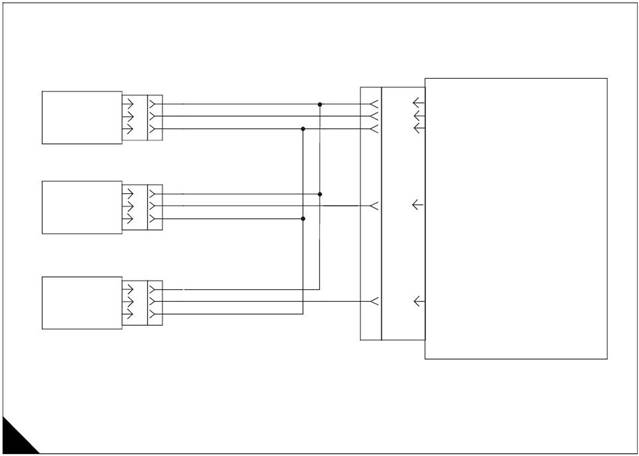

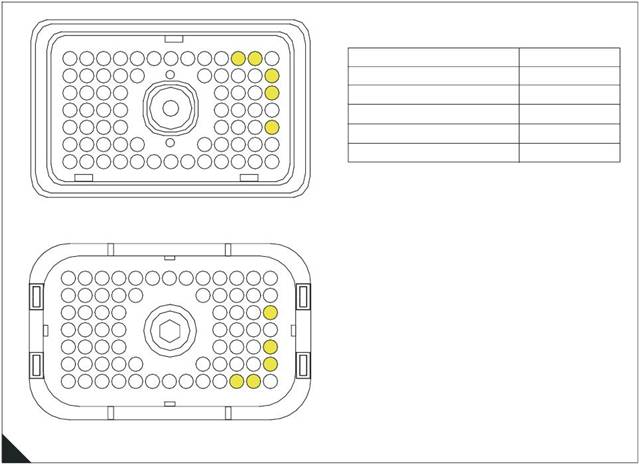

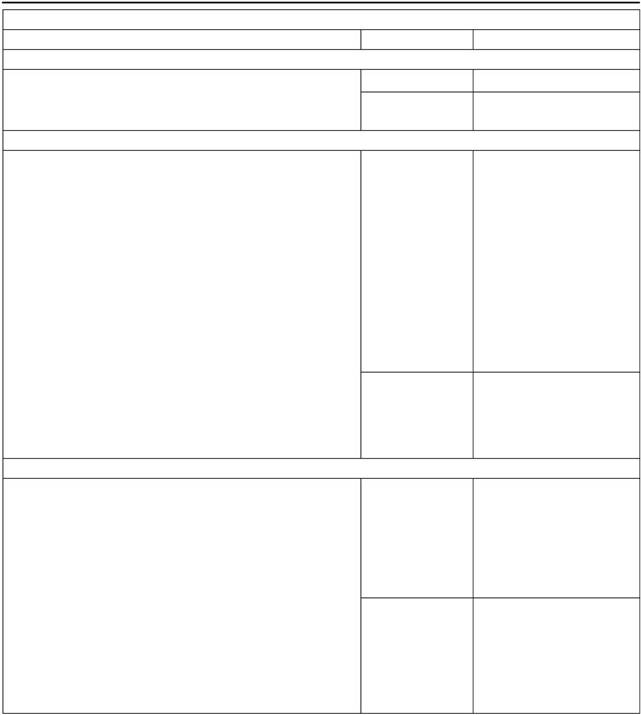

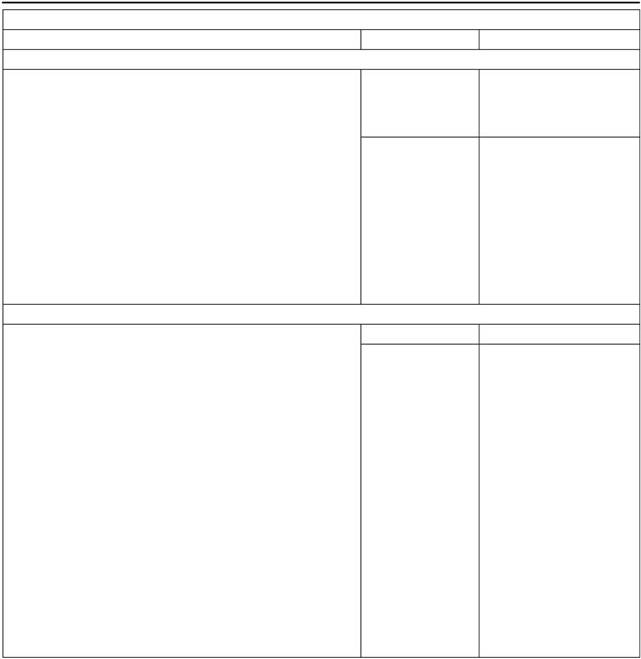

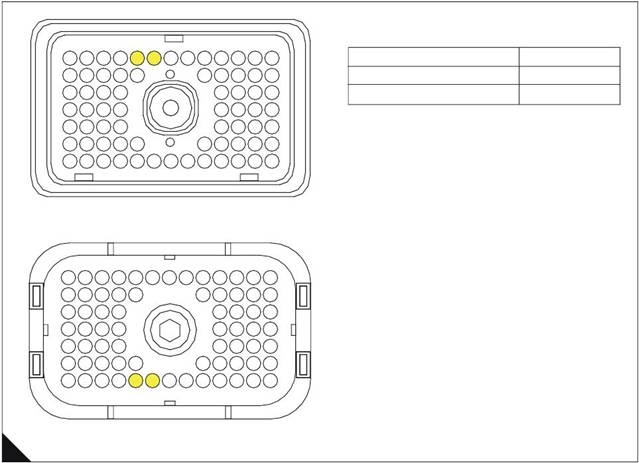

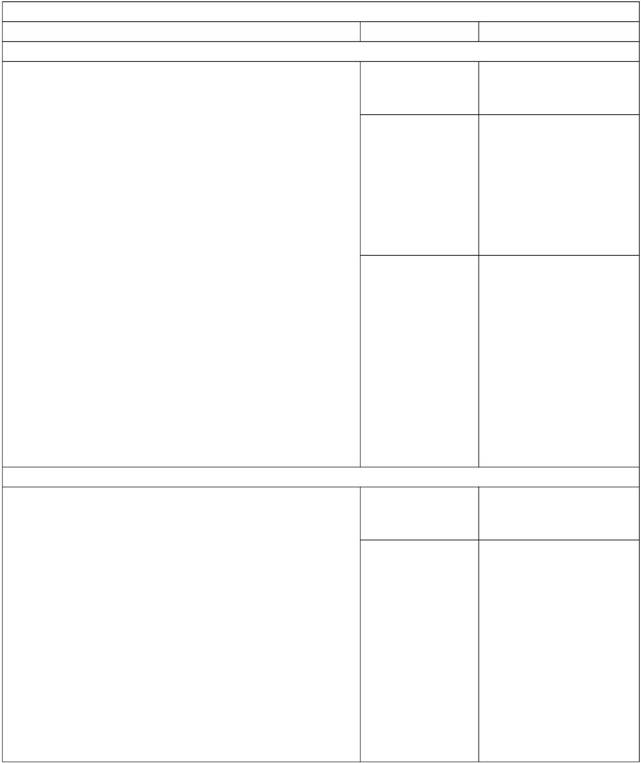

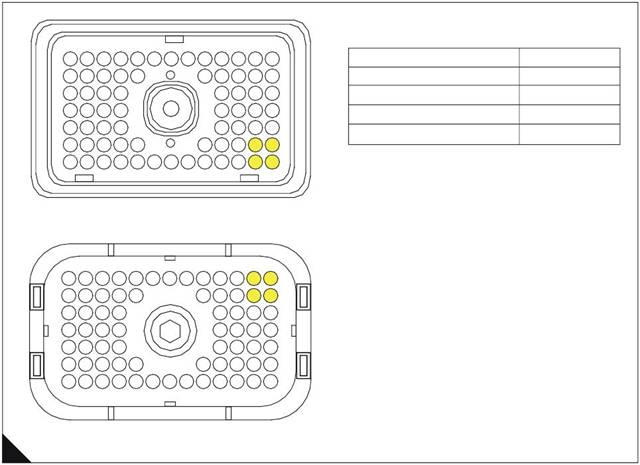

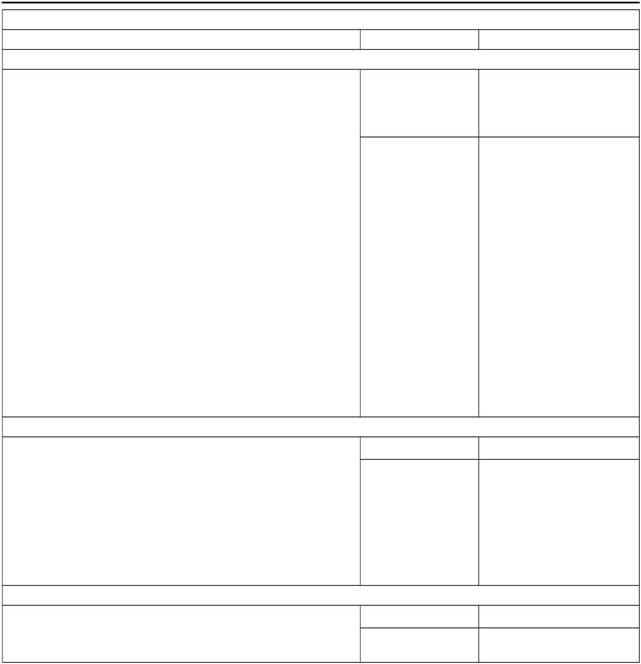

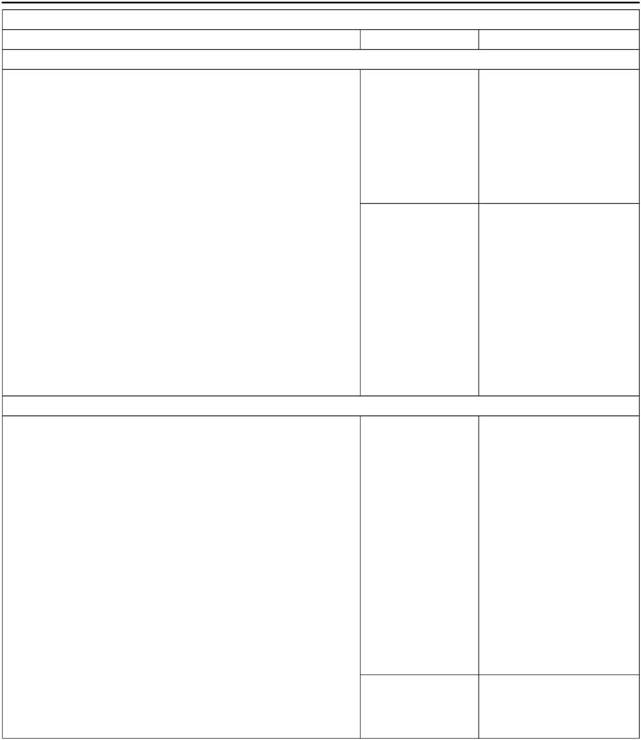

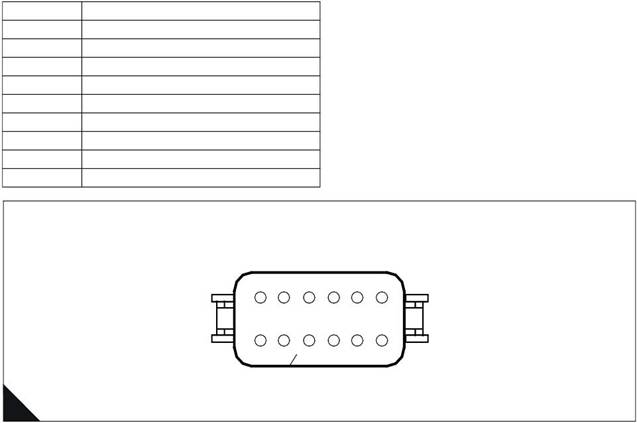

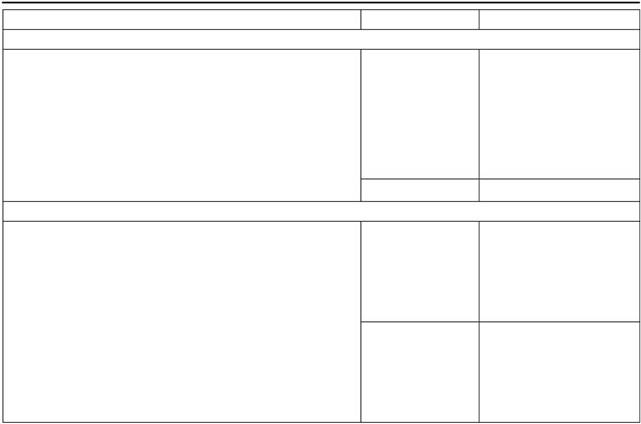

ECM terminal connections

Note: Using ECM connector P1.

2800 Series

13 12

11

10

9

8

7

6

5

4

3

2

1

Function

Pin Location

23

22

21 20

19

18

17

16

15

14

Shutdown Lamp

10

31

39

47

57

30

38

46

56

29 28

37 36

45 44

55 54

53

52

27 26

35 34

43 42

51 50

25

33

41

49

24

32

40

48

Action Alert Lamp

Warning Lamp

Diagnostics Lamp

Oil Pressure Lamp

19

20

31

28

70

69

68

67 66

65

64

63

62

61

60

59

58

Coolant Temp Lamp

Overspeed Lamp

Crank Terminate Output

29

30

Terminal side

13

57

47

31

70

69

68

67

66

36

65

64

63

62

61

60

59

58

48

40

24

23

13

12

11

10

9

>PEI<

8 7

6

5

4

3

2

1

14

B

Wire side

HA0020

106

![]()

![]()

![]()

![]() 2800 Series

2800 Series

4

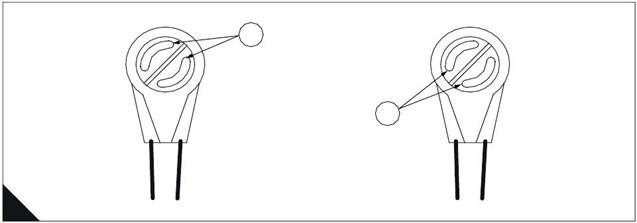

+5 V Sensor voltage supply circuit test

Test 43

Diagnostic codes

System operation

Functional test

Use this procedure to diagnose the system when there is an active, or easily repeated, 262-03 +5 V Supply

Above Normal or 262-04 +5 V Supply Below Normal or if directed here by another diagnostic procedure.

The Electronic Control Module (ECM) supplies +5 V to the oil pressure, atmospheric pressure and turbo outlet

pressure sensors. The +5 V sensor supply is routed from the ECM through the ECM engine harness connector

J2/P2 terminal-2 to terminal-A of each +5 V sensor connector. The supply voltage is 5.0 +/- 0.5 Volts DC.

The +5 V short circuit diagnostic code is most likely caus ed by a short or open circuit in the harness, next likely

is a sensor, and least likely is the ECM.

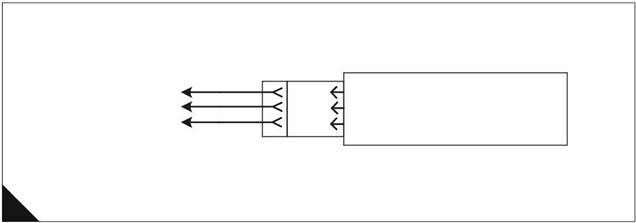

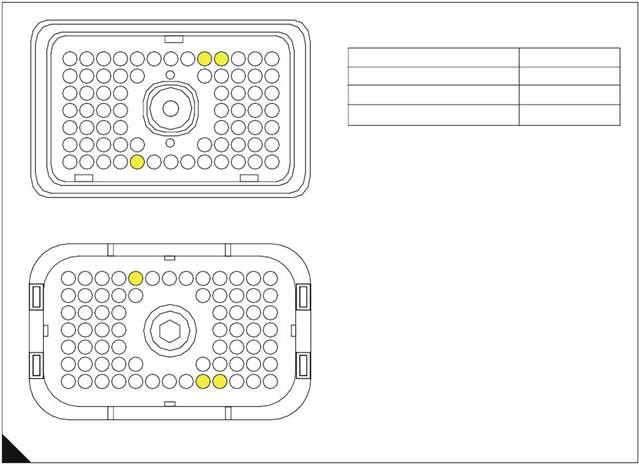

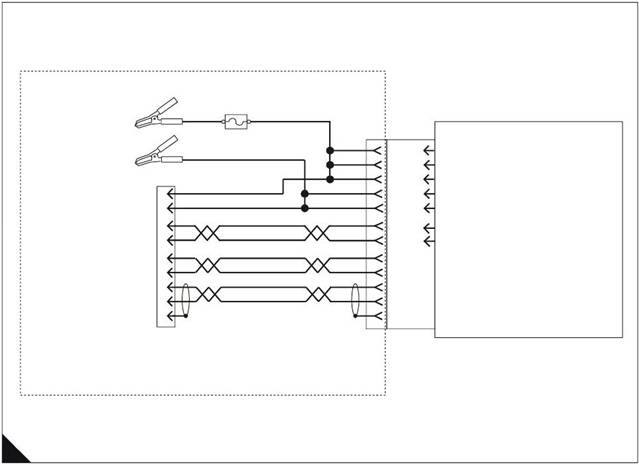

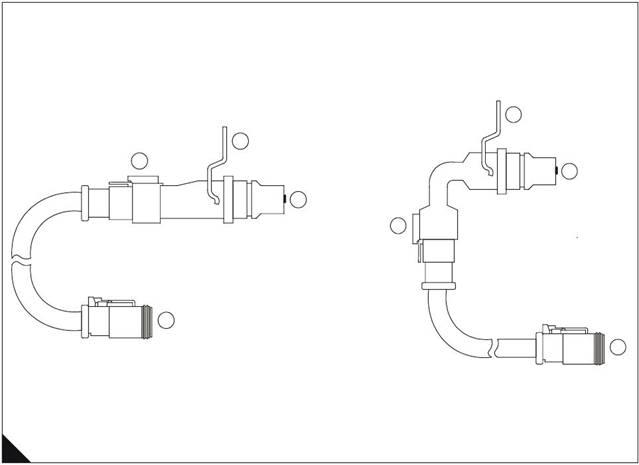

5 V supply to analogue sensor schematic

Note: Refer to the wiring diagrams for full connection details.

|

|

|

|

Return B

Turbo Outlet Pressure Sensor

Return B

J2/2

J2/14

J2/3

J2/40

+5VDC Suppl y

Atmospheric Pressure

Analogue Return

ECM

Intake Manifold Pressure

|

|

Return

A

C

B

J2/24

Oil Pressure

A

HA0021

107

![]() 4

4

Diagnostic codes

2800 Series

|

Diagnostic fault code |

Conditions that could cause the code |

System response |

To find the fault |

|

262-03 |

+5 V Supply Above Normal The ECM supply voltage for the sensors is exceeding normal level, indicating a possible short to a positive voltage source. |

Electronic system response All ECM +5 V analogue sensor inputs assume default values and all diagnostic codes for ECM +5 V analogue sensors are disabled while this diagnostic code is active. TIPSS may indicate DIAG next to the default value Sensor Status to indicate the sensor is operating at the value shown due to an active diagnostic code. This diagnostic code remains active until the engine control switch is turned to the OFF position. Note: Since engine protection is no longer available, the engine is shut down. |

Proceed with Test 43: +5 V Sensor voltage supply circuit test. |

|

262-04 |

+5 V Supply Below Normal The ECM supply voltage for the intake manifold pressure, atmospheric pressure and oil pressure sensors is below normal level, indicating a possible short to ground or short between sensor supply and return. |

Electronic system response All ECM +5 V analogue sensor inputs assume default values and all diagnostic codes for ECM +5 V analogue sensors are disabled while this diagnostic code is active. TIPSS may indicate DIAG next to the default value Sensor Status to indicate the sensor is operating at the value shown due to an active diagnostic code. This diagnostic code remains active until the key switch is turned to the OFF position. Note: Since engine protection is no longer available, the engine is shut down. |

Proceed with Test 42: ECM Status indicator output circuit test. |

108

![]() 2800 Series

2800 Series

Functional test

4

Test 43 - +5 V Sensor voltage supply circuit test

Test step Result

Step 1: Connect an electronic service tool and note all active diagnostic codes

Connect the TIPSS-EST service tool to the service tool ACTIVE

connector.

Turn the key switch to the ON position.

Access the TIPSS "Active" and "Logged Diagnostic Code" LOGGED ONLY

screen(s) (wait at least 15 seconds for diagnostic codes to

become active).

Check for active or logged 262-03 +5 V Supply Above Normal

or 262-04 +5 V Supply Below Normal diagnostic codes.

Select the condition of code 262-03 or 262-04.

NOT ACTIVE OR

LOGGED

Step 2: Disconnect +5 V sensors and monitor active diagnostic codes

Access the "Active Diagnostic Code" screen and check there is

an active +5 V Sensor Supply diagnostic code (262-03 or

262-04).

Disconnect the following sensors and turn the key switch to the

OFF position, then to the ON position: oil pressure,

atmospheric pressure and turbo outlet pressure sensors.

Check the TIPSS-EST screen after disconnecting each sensor

to determine if disconnection of a specific sensor deactivates

the +5 V diagnostic code.

Note: When the sensors are disconnected and the key switch is in

the ON position, open circuit diagnostic codes will be active/logged

when the +5 V diagnostic codes are no longer acti ve. This is

normal. Clear these diagnostic codes after this test step is

completed.

Is the original +5 V diagnostic code (262-03 or 262-04) still

active ?

Action

A 262-03 or 262-04

diagnostic code is active.

Go to step 2.

A 262-03 or 262-04

diagnostic code is logged

but NOT active.

Refer to Test 39: Inspecting

electrical connectors on

page 82.

If OK, Go to step 4..

The +5 V sensor supply is

operating correctly at this

time.

STOP.

The +5 V diagnostic code is

still active.

Leave the sensors

disconnected.

Go to step 3.

Disconnecting a specific

sensor makes the +5 V

diagnostic code no longer

active.

Reconnect the sensor

suspected of causing the

problem.

If the problem reappears,

and then disappears

following disconnection,

renew the sensor.

Clear all diagnostic codes.

Check that the repair

eliminates the fault.

STOP.

109

![]() 4

4

2800 Series

Test 43 - +5 V Sensor voltage supply circuit test (Continued)

Test step Result

Step 3: Isolate the sensor supply harness From The ECM

Action

Remove power from the engine control system. Turn the key

switch to the OFF position and disconnect the power from the

engine.

Disconnect J2/P2 and inspect for damage or corrosion. Repair

as necessary.

Use a wire removal tool to remove the +5 V supply wire from

ECM connector P2 terminal-2. Reconnect J2/P2.

Restore power to the engine control system and turn the key

switch to the ON position.

Access the "Active Diagnostic Code" screen and determine

there is an active +5 V Sensor Supply diagnostic code (262-03

or 262-04).

Does the +5 V diagnostic code remain active with the engine

harness isolated ?

Step 4: Check the engine harness

Remove power from the engine control system. Turn the key

switch to the OFF position and disconnect the power from the

engine.

Disconnect P2 and check ALL of the +5 V engine sensors

attached to the P2 engine harness are di sconnected (oil

pressure, atmospheric pressure and turbo outlet pressure

sensors).

Set a multimeter to measure resistance on the range closest to,

but not less than, 2k Ohms. Measure from P1 terminal-2 (+5 V

Supply) to each of the sensor signal terminals (P1

terminals-14, 17, 24, 26, and 27) and to P1 terminal-3

(analogue return). Wiggle the harness during measurement to

reveal any intermittent short condition. Refer to "ECM terminal

connections" on page 111.

Measure the resistance from P2 terminal-2 (+5 V Supply) to

engine ground.

Each resistance measurement is more than 2k Ohms.

Isolating the engine harness

from the ECM does not

eliminate the active +5 V

Sensor Supply diagnostic

code.

Renew the ECM.

STOP.

The +5 V Sensor Supply

diagnostic code is no longer

active when the harness is

isolated.

There is a short circuit in the

harness.

Refer to Test 39: Inspecting

electrical connectors on

page 82.

If OK, Go to step 4..

The +5 V line is not shorted

in the engine harness.

Reconnect all connectors.

There does not appear to be

a problem at this time.

Clear all diagnostic codes.

Continue to diagnose until

the original condition is

resolved.

STOP.

Repair the engine harness.

Clear all logged diagnostic

codes.

Check that the repair

eliminates the fault.

STOP.

110

![]() 2800 Series

2800 Series

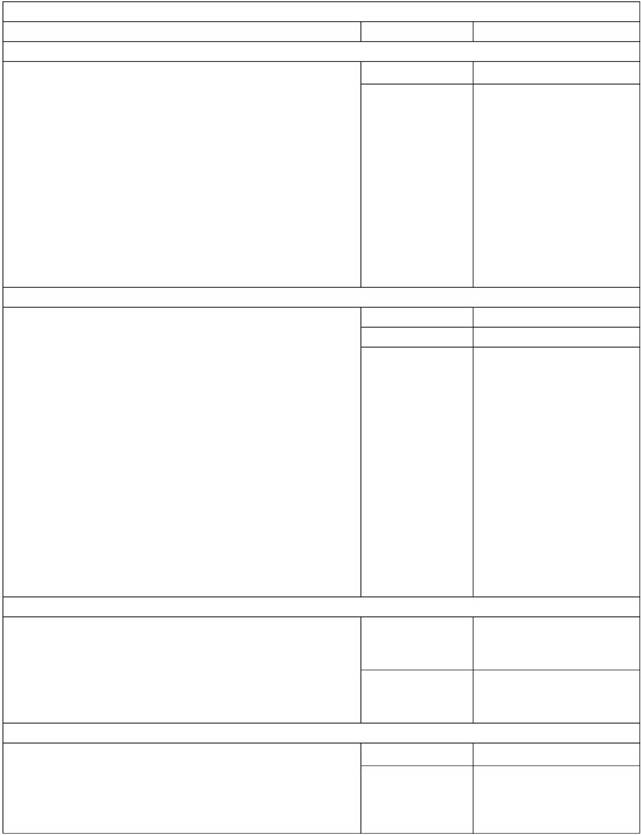

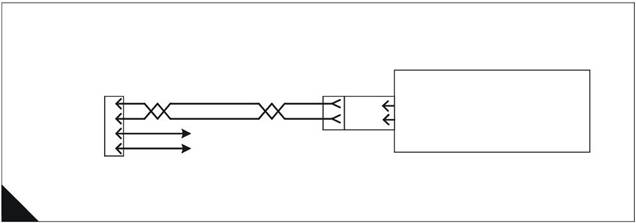

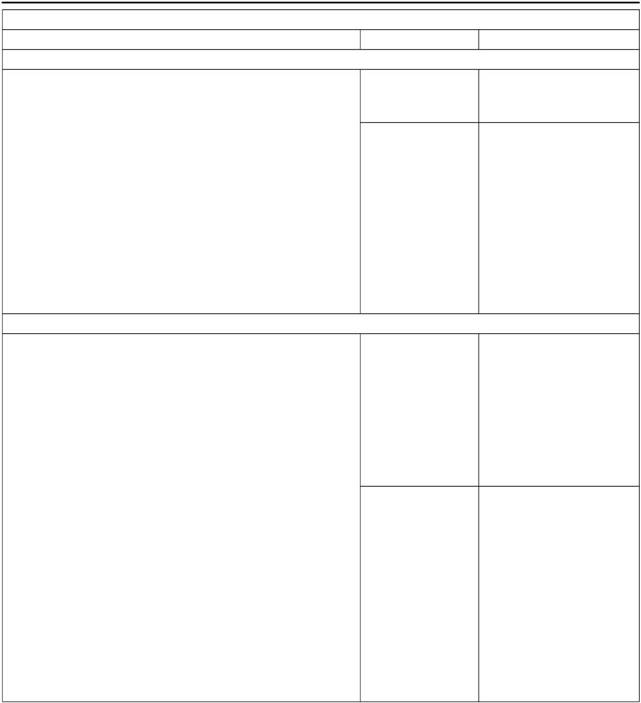

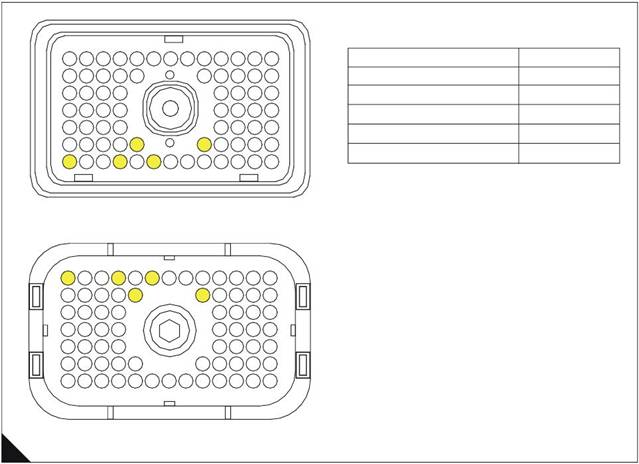

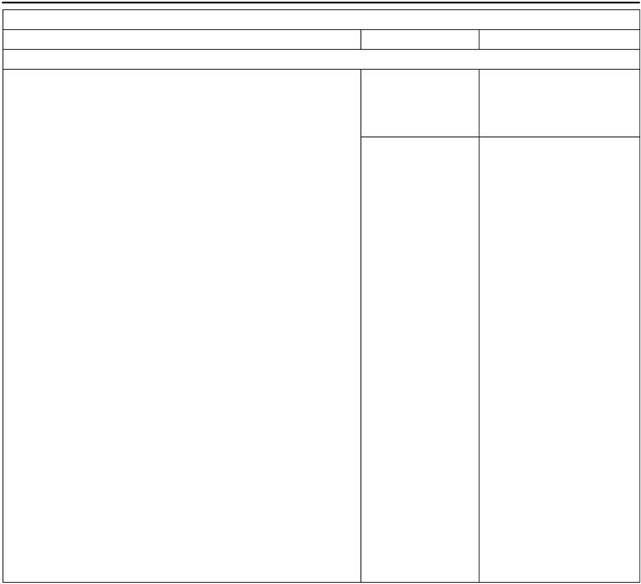

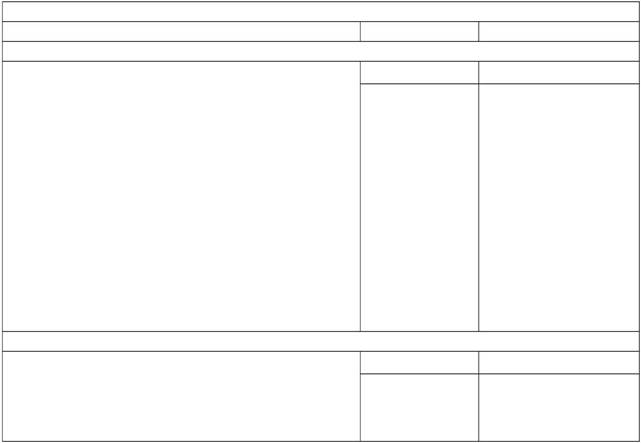

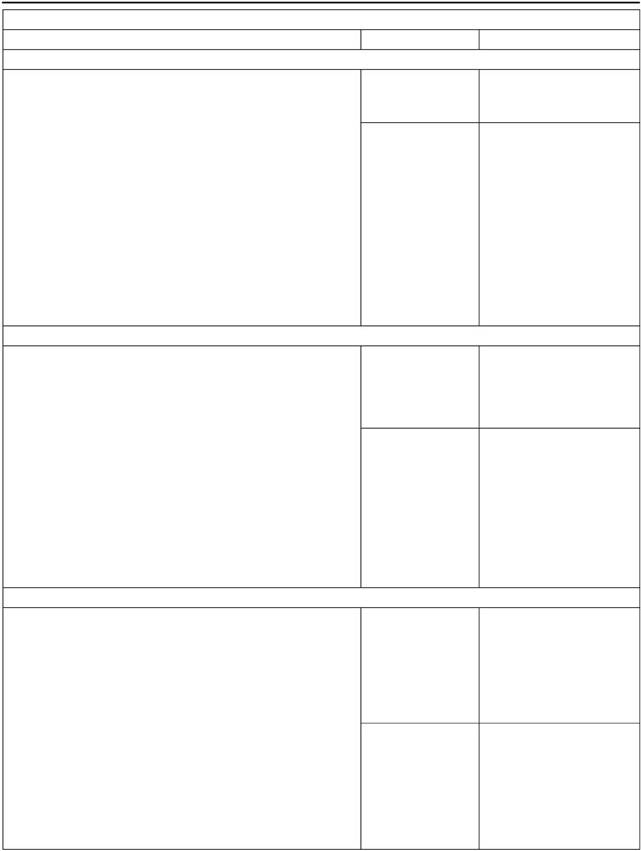

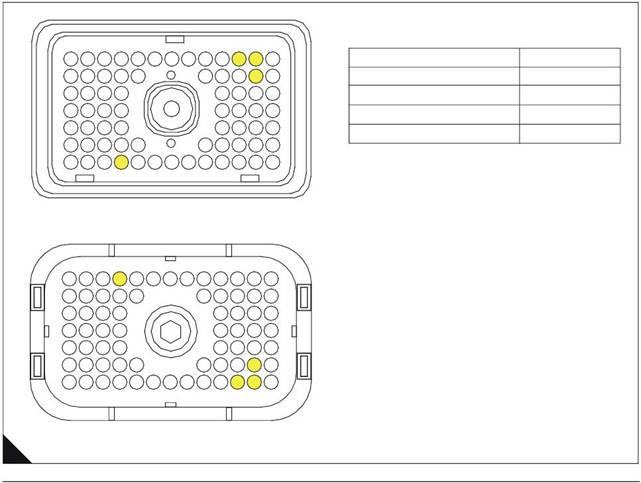

ECM terminal connections

Note: Using ECM connector P2.

4

13

23

31

12

22

30

11

21

29

10

20

28

9

19

8

7

6

5

18

4

17

27

3

16

26

2

15

25

1

14

24

Function

+5 VDC Supply

Analog Return

Pin Location

2

3

39

47

57

38

46

56

37 36

45 44

55 54 53

52

35

43

51

34

42

50

33 32

41 40

49 48

Intake Manifold Pressure

Atmospheric Pressure

Oil Pressure

40

14

24

70

69

68

67 66

65

64 63

62 61

60

59 58

Terminal side

57

47

31

23

70

69

68

67 66

36

65

64

63

62 61

60

59 58

48

40

24

14

13

12

11

10

9

>PEI<

8 7

6

5

4

3

2

1

B

Wire side

HA0022

111

![]()

![]()

![]()

![]() 4

4

2800 Series

PWM desired speed setting circuit test

Test 44

Diagnostic codes

System operation

Functional test

Note: This procedure is only applicable if the PWM speed control method is selected.

Use this procedure if a 91-08 Invalid PWM Speed Control Signal, 41-03 8 Volt Supply Above Normal or 41-04

8 Volt Supply Below Normal diagnostic code is indicated.

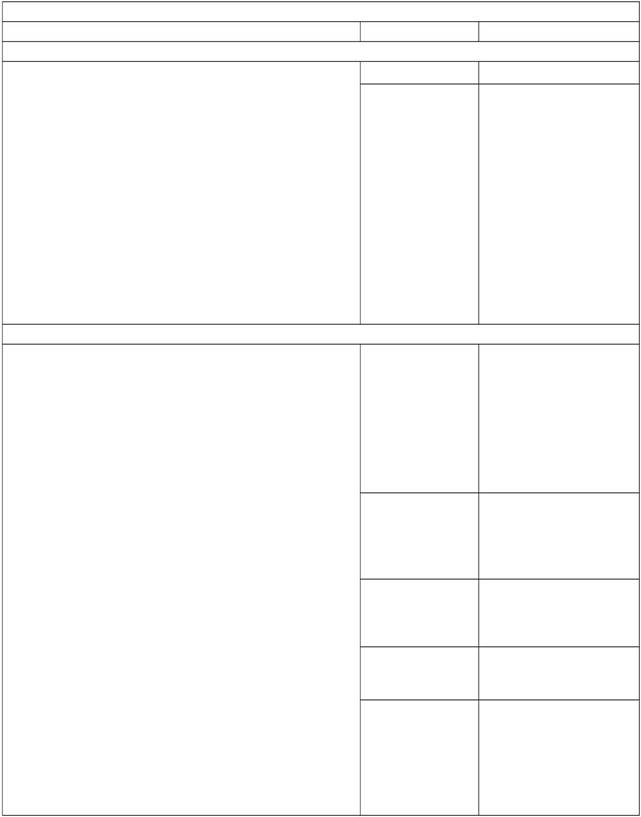

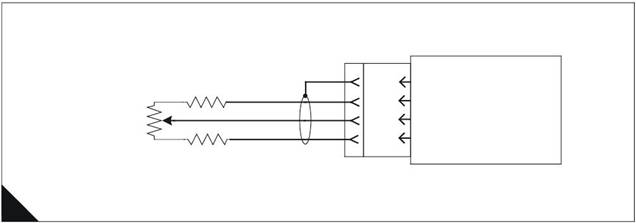

PWM speed control

The PWM speed control is used to provide a desired speed setting signal to the ECM. Output is a constant

frequenc y signal with a pulse width that varies with the speed control signal. This output signal is referred to

as either “Duty Cycle” or a “Pulse Width Modulated” (PWM) signal and is expressed as a percentage between

3 and 100 percent.

Note: The PWM speed control is an external device supplied by the OEM.

The speed control must produce a duty cycle of 2.6 to 9.9 percent for 1141 rev/min (1369 rev/min if 1800 rev/

min is selected) and 90.1 to 95 percent for full speed of 1621 rev/min (1945 rev/min is 1800 rev/min is

selected).

The PWM speed control may be powered by the ECM supplied from +8 V from connector P1 terminal-4.

If PWM speed control is selected but there is no PWM input, the engine will run at 1100 rev/min.

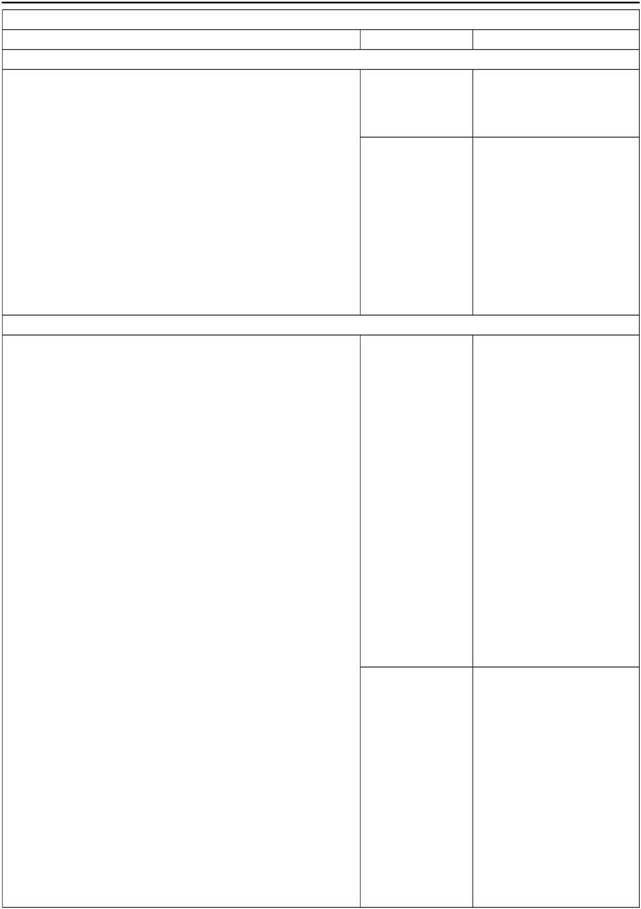

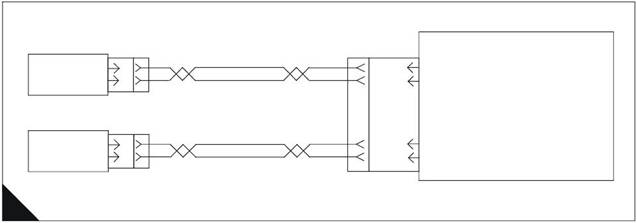

PWM Speed control circuit

Note: Refer to the wiring diagrams for full connection details.

To OEM

Supplied PWM

Speed Control

J1/5

J1/4

J1/66

P1 J1

Ground

+ 8V

PWM Input

ECM

A

HA0023

112

![]() 2800 Series

2800 Series

Diagnostic codes

4

|

Diagnostic fault code |

Conditions that could cause the code |

System response |

To find the fault |

|

41-03 |

8 Volt Supply Above Normal The PWM speed control supply voltage is higher than it should be. |

Engine response An active diagnostic code may not cause any noticable effect on engine response unless the voltage is significantly above 8 volts. The engine may be limited to low idle. |

Proceed with Test 44: PWM desired speed setting circuit test. |

|

41-04 |

8 Volt Supply Below Normal The PWM speed control supply voltage is lower than it should be. |

Engine response An active diagnostic code may not cause any noticable effect on engine response unless the voltage is significantly below 8 volts. The engine may be limited to low idle. |

Proceed with Test 44: PWM desired speed setting circuit test. |

|

91-08 |

Invalid PWM Speed Control Signal The ECM is not receiving a correct speed control signal from either the PWM or analogue speed control input, according to the control selected. |

Electronic system response The ECM returns the engine to nominal speed as soon as the problem is detected. The diagnostic code is only logged if the engine is running. Engine response The engine will remain at nominal speed while the diagnostic code is active. If there is no PWM input, the engine will run at 1100 rev/min. |

The diagnostic code is most likely caused by an open circuit in the PWM or analogue speed control signal circuit, or voltage supply circuit. Proceed with Test 44: PWM desired speed setting circuit test. |

113

![]() 4

4

Functional test

2800 Series

|

Test step Result

Step 1: Inspect electrical connectors and wiring

Thoroughly inspect ECM connector J1/P1, the OEM connector

and the external wiring. Refer to Test 39: Inspecting electrical

connectors on page 82.

Perform a 45 N (10 lb) pull test on each of the wires in the ECM

connector P1 associated with the PWM speed control

(terminals 3, 4, 5, 66 and 68). Refer to "ECM terminal

connections" on page 117.

Check that the ECM connector All en screw is correctly

tightened to not more than 3,0 Nm (2.2 l b ft) 0,31 kgf m.

Check the harness and wiring for abrasion and pinch points

from the sensor back to the ECM.

All connectors, pins and sockets are completely mated/

inserted, and the harness/wiring is free of corrosion, abrasion

or pinch points.

Step 2: Check for active diagnostic codes

Connect an electronic service tool to the data link connector. RESULT 1

Turn the key switch ON, engine OFF. RESULT 2

screen, check and record active diagnostic codes.

Note: When the ECM is first powered it automatically calibrates

new duty cycle values for the low and high speed positions. It

assumes 10 percent at low speed and 95 percent for the high

speed duty cycle. Following some cycling of the speed input

between the low and high positions, the ECM will adjust its

calibration automatically, provided that the high idle stop position is

within the 90 to 95 percent duty cycle range and the low speed is

in the 2.6 to 9.9 percent duty cycle range.

Result 1 - Diagnostic code 91-08 is active.

Result 2 - Diagnostic code 41-03 or 41-04 is active.

Result 3 - There are no active diagnostic codes that are related

to the speed control circuit at this time, but a problem is

suspected with its operation.

Step 3: Check PWM speed control duty cycle

Connect an electronic service tool to the data link connector (if

not already installed).

Turn the key switch ON, engine OFF

Monitor the speed control range on the electronic service tool.

Is the PWM speed control operating correctly ?

Step 4: Check PWM speed control supply voltage at the speed control

Connect a voltmeter to the +8 V and ground terminals.

Turn the key switch ON, engine OFF.

Measure the voltage at the +8 V supply with reference to

ground.

Is the measured voltage between 7.5 and 8.5 Volts DC ?

Action

Go to step 2.

Repair or renew wiring or

connectors as necessary.

Ensure that all seals are

correctly installed and that

connectors are completely

mated.

Check that the repair

eliminates the fault.

If the conditions are not

resolved, Go to step 2.

Go to step 3.

Go to step 5.

Go to step 3.

The PWM speed control is

currently operating correctly.

STOP.

The PWM speed control is not

operating correctly.

Go to step 4.

Go to step 7.

The speed control is not

receiving the correct voltage.

Go to step 5.

114

![]() 2800 Series

2800 Series

4

Test 44 - PWM desired speed setting circuit test (Continued)

Test step Result

Step 5: Disconnect PWM speed control while monitoring active diagnostic codes

Action

Access the "Active Diagnostic Code" screen of the electronic

service tool. Ensure that either a 41-03 8 Volt Supply Above

Normal or 41-04 8 Volt Supply Below Normal diagnostic code

is active before proceeding.

Monitor the "Active Diagnostic Code" screen while

disconnecting and reconnecting the PWM speed control.

Is the 41-03 8 Volt Supply Above Normal or 41-04 8 Volt Supply

Below Normal still active after the control is disconnected ?

Step 6: Disconnect PWM speed control supply terminals at the ECM

Turn the key switch OFF, engine OFF.

Remove terminal-4 (+8 V) and terminal-5 (SENSOR/ SWITCH

SENSOR COMMON) from machine harness connector P1

(disconnect ECM harness connector J1/P1 if necessary).

Reconnect ECM connector J1/P1.

Turn the key switch ON, engine OFF.

Use an electronic service tool and check if the diagnostic code

is still active.

Is the 41-03 8 Volt Supply Above Normal or 41-04 8 Volt Supply

Below Normal still active after the power terminals are

disconnected ?

Ensure the speed control has

been reconnected before

continuing.

Go to step 6.

Temporarily install another

PWM speed control.

Use an electronic service tool

and check if the +8 V

diagnostic code is still active.

If the problem is corrected

with the new speed control

and returns when the old

speed control is connected,

renew the speed control.

STOP.

Check the battery voltage

from P1 terminal-61 and

terminal-63 (UNSWITCHED

+BATTERY) to terminal-48

and terminal-52 (-BATTERY)

to ensure that it is 22.0 to 27.0

Volts DC for a 24 Volt system.

If the battery voltage is

correct, temporarily connect a

test ECM.

Use an electronic service tool

and check if the di agnosti c

code is still active.

If the problem is corrected

with the test ECM, reconnect

the old ECM and check that

the problem returns.

If the test ECM works and the

old ECM does not, renew the

ECM.

STOP.

There is a problem in the

wiring between the ECM and

the PWM speed control.

Connect the removed wires

one at a time while watching if

the diagnostic code

reappears. First connect

terminal 5 and then connect

terminal 4 to determine which

is causing the problem.

Repair or renew the damaged

wires as necessary.

Check that the repair

eliminates the fault.

STOP.

115

![]() 4

4

2800 Series

Test 44 - PWM desired speed setting circuit test (Continued)

Test step Result

Step 7: Check PWM speed control duty cycle at the speed control

Action

Refer to OEM instructions for the correct procedure.

Step 8: Check PWM speed control duty cycle at the ECM

Turn the key switch OFF, engine OFF.

Use a multimeter capable of measuring PWM duty cycle.

Remove the speed control wire (terminal-66) from the machine

harness side (P1) of ECM connector P1/J1. It may be

necessary to disconnect ECM connector P1 in order to remove

the speed control signal terminal.

Connect multimeter probes between the removed wire and

terminal 5 (SENSOR/SWITCH SENSOR COMMON) of P1.

Reconnect ECM connector P1 to the ECM.

Turn the key switch ON, engine OFF.

Use the multimeter to display the duty cycle output of the PWM

speed control while moving the sensor assembly from low idle

to high idle. Record the results.

Does the duty cycle measure between 10 percent at the low

speed position and increase to 90 percent in the high speed

position ?

Turn the key switch OFF, engine OFF.

Insert terminal-66 into the 70-terminal ECM connector P1/J1.

Step 9: Route supply bypass wires to the PWM speed control

Turn the key switch OFF, engine OFF.

Remove the speed control wire (terminal-66) from the ECM

connector P1.

Route new wiring from the ECM to the external speed control.

Turn the key switch ON, engine OFF.

Check the speed control duty cycle with an electronic service

tool while changing the speed setting over the full range.

Does the duty cycle measure between 10 percent at the low

speed position and increase to 90 percent in the high speed

position ?

Go to step 8.

Renew the speed control unit.

STOP.

A good speed control signal is

reaching the ECM.

Check that the ECM is

receiving the correct battery

voltage. If so temporarily

connect a test ECM.

If the problem disappears with

the test ECM connected,

reconnect the suspect ECM

to check that the problem

returns. If the test ECM works

and the old one does not,

renew the ECM.

STOP.

There is a problem with speed

control signal wire in the

machine wiring harness.

Go to step 9.

The wiring from the ECM to

the speed control appears

faulty.

Renew the wiring.

Check that the repair

eliminates the fault.

STOP.

Double check the wiring, the

ECM machine harness

connector J1/P1 and the

connectors.

If a problem still exists, restart

the test procedure.

STOP.

116

![]() 2800 Series

2800 Series

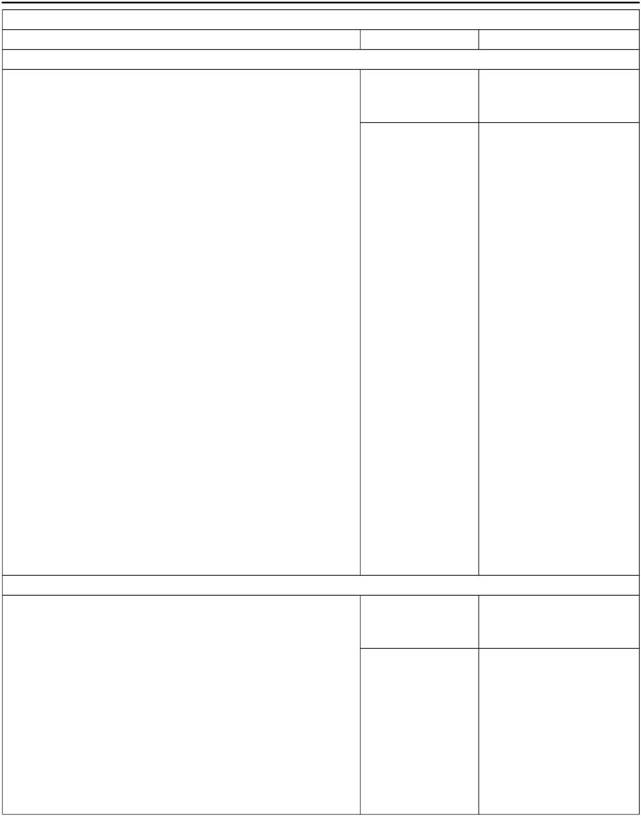

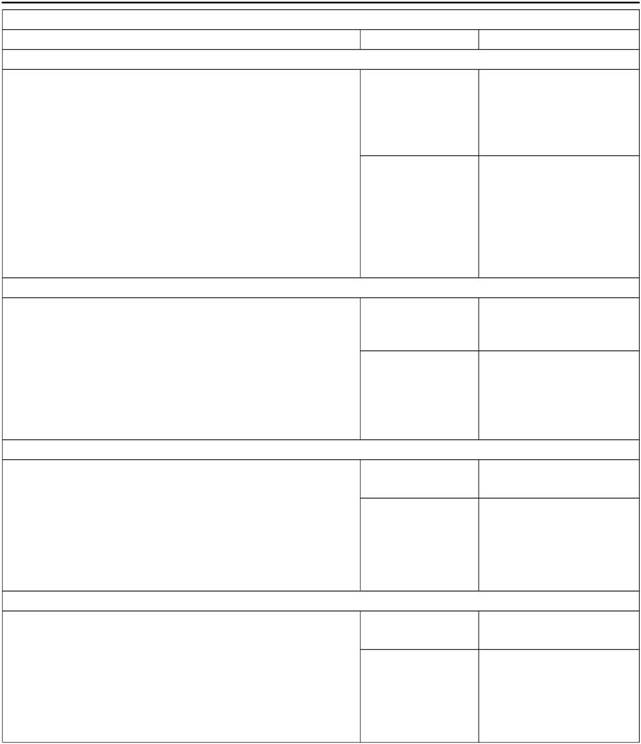

ECM terminal connections

Note: Using ECM connector P1.

4

13

23

31

12

22

30

11

21

29

10

20

28

9

19

8

7

6

5

18

4

17

27

3

16

26

2

15

25

1

14

24

Function

Ground

+ 8V

Pin Location

5

4

39

47

57

38

46

56

37 36

45 44

55 54 53

52

35

43

51

34

42

50

33 32

41 40

49 48

PWM input

66

70

69

68

67 66

65

64 63

62 61

60

59 58

Terminal side

57

47

31

70

69

68

67 66

36

65

64

63

62 61

60

59 58

48

40

24

23

13

12

11

10

9

>PEI<

8 7

6

5

4

3

2

1

14

B

Wire side

HA0024

117

![]()

![]()

![]() 4

4

2800 Series

Perkins Data Link circuit test

Test 45

Functional test

System operation

Use this procedure if the electronic service tool will not power up or communicate with the ECM through the

data link.

Background

The Perkins Data Link is the standard data link used by the ECM to communicate with electronic service tools

such as TIPSS-EST.

The ECM provides two data link connection terminals from the ECM machine harness connector J1, terminal-

9 (DATA LINK NEGATIVE) and terminal-8 (DATA LINK POSITIVE).

The OEM provides twisted pair wiring from the ECM to the data link connector.

Communication with the key switch OFF

With the key switch OFF, the ECM will not communicate with the electronic servic e tool. In order to avoid this

problem turn the key switch ON when working with the electronic service tool.

TIPSS-EST may indicate an error message that the ECM version is not recognized and the integrity of the

changed parameters and displayed data is not guaranteed. This will indicate that y ou have not installed the

latest release of the TIPSS-EST software or the ECM software is newer than the TIPSS-EST software.

Perkins Data Link schematic

Note: Refer to the wiring diagrams for full connection details.

9 Pin

Perkins

D

E

Battery +

J1/8

J1/9

ECM

Perkins Data Link +

Perkins Data Link -

Data Link A

Connector B

Battery -

P1 J1

A

HA0025

118

![]() 2800 Series

2800 Series

Functional test

4

Test step

Test 45 - Perkins Data Link circuit test

Result

Action

Step 1: Check electrical connectors and wiring

Thoroughly inspect the ECM machine harness connector J1/

P1, data link connector, electronic service tool connectors and

cables, and the Perkins Data Link (terminals-8 and 9) in the

connectors.

Refer to "ECM terminal connections" on page 123.

Refer to Test 39: Inspecting electrical connectors on page

82.

Perform a 45 N (10 lb) pull test on each of the wires in the

connectors associated with the Perkins Data Link.

Check that the ECM connector Allen screw is correctly

tightened to not more than 3,0 Nm (2.2 lb ft) 0,31 kgf m.

Check the harness and wiring for abrasion and pinch points

from the sensor back to the ECM.

All connectors, pins and sockets are completely mated/

inserted and the harness/wiring is free of corrosion, abrasion

or pinch points.

Step 2: Determine the type of data link problem

Connect an electronic service tool to the data link connector.

Start the engine.

Result 1 - Engine starts and electronic service tool powers up

and communicates without error.

Result 2 - Engine starts and electronic service tool powers up

but displays an error.

Result 3 - Engine cranks but will not start regardless of the

condition of the electronic service tool.

Result 4 - Engine will not crank regardless of the condition of

the electronic service tool.

Result 5 - Engine starts but the electronic service tool does

not power up.

Note: To determine if the electronic service tool has powered up,

check the display screen or check the communication adapter

display. The electronic service tool will display information that

shows if the tool is getting power, and will be blank if it is not. If the

electronic service tool or the communication adapter powers up,

the data link connector is receiving power.

RESULT 1

RESULT 2

RESULT 3

RESULT 4

RESULT 5

Go to step 2.

Renew or repair wiring or

connectors as necessary.

Ensure all seals are correctly

installed and that connectors

are completely mated.

Check that the repair

eliminates the fault.

STOP.

There is not a problem with

the data link at this time.

If an intermittent condition

exists, thoroughly inspect all

wiring and connectors.

Refer to Test 39: Inspecting

electrical connectors on

page 82

STOP.

The electronic service tool

displays an error message.

The ECM is receiving battery

power.

Go to step 5.

Refer to Test 2: Engine

cranks but will not start on

page 38.

STOP.

Refer to Test 1: Engine will

not crank on page 37.

STOP.

The electronic service tool or

communications adapter

does not power up.

Ensure that the ECM is

receiving the correct battery

power.

Go to step 3.

119

![]() 4

4

2800 Series

|

Test step Result

Step 3: Check the battery voltage supply to the data link connector

Turn the key switch ON, engine OFF

Use a multimeter to measure the voltage from the data link

connector + BATTERY terminal to the - BATTERY terminal.

Refer to "Pin allocation for communications connector" on page

123.

Is the voltage is between 22.0 and 27.0 Volts for a 24 Volt

system ?

Step 4: Change electronic service tool components

If another engine or ECM is available connect the electronic RESULT 1

RESULT 2

Turn the key switch ON, engine OFF. Determine if the

electronic service tool operates correctly on the other engine. If

another engine is not available, find a different set of electronic

service tool cables.

Connect the electronic service tool to the data l ink connector

using the new cables.

Turn the key switch ON, engine OFF.

If changing cables allows the electronic service tool to operate

correctly, replace (one at a time) the pieces from the old cable

set into the one that does operate and repower the electronic

service tool each time to determine which piece is faulty.

If changing cables does not allow the electronic service tool to

operate correctly, connect a different electronic service tool.

Turn key switch to the ON, engine OFF.

Result 1 - The original electronic service tool works on

another engine.

Result 2 - A different electronic service tool works on the

original engine while the engine is being tested.

Action

The data link connector is

currently receiving the

correct voltage.

Go to step 4.

The data link connector is

not receiving the correct

voltage.

Inspect the wiring and fuses

to the connector.

Repair or renew the wiring or

batteries as required.

Check that the repair

eliminates the fault.

STOP.

Go to step 5.

Send the faulty electronic

service tool for repair.

STOP.

120

![]() 2800 Series

2800 Series

4

Test 45 - Perkins Data Link circuit test (Continued)

Test step Result

Step 5: Check battery voltage at the ECM

Ensure that the electronic service tool is connected to the data

link connector.

Disconnect the ECM machine harness connector J1/P1 and

insert a 70-terminal breakout T in series, or if signal reading

probes are available and ECM connector P1 is accessible

(without disconnecting), insert probes into terminal-52

(UNSWITCHED +BATTERY) and terminal-65 (-BATTERY).

Refer to "Breakout connector" on page 124.

Turn the key switch ON, engine OFF.

Measure the voltage between ECM connector PP terminal-52

(UNSWITCHED +BATTERY) and terminal-65 (-BATTERY).

Measure the voltage between P1 terminal-70 (KEY SWITCH)

and terminal-65 (- BATTERY).

The voltage, , is between 22.0 and 27.0 Volts with the key switch

ON ?

Step 6: Connect the electronic service tool directly to the ECM

Warnings!

Batteries give off flammable fumes which can explode. Do not

strike a match, cause a spark, or smoke in the vicinity of a

battery during the test procedure.

Do not connect the electronic service tool bypass harness to

the battery until the 20 Amp in-line fuse has been removed from

the +Battery line. If the fuse is not removed before connection

to the battery a spark may result.

Turn the key switch OFF, engine OFF.

Disconnect the ECM machine harness connector J1/P1 from

the ECM.

Install an electronic service tool power bypass cable. Connect

the bypass directly to the electronic service tool harness and

ECM. Refer to "Service tool bypass harness schematic" on

page 125.

Note: This bypass connects the key switch circuit directly to the

ECM. The ECM will remain powered until the connection to the

+BATTERY line is disconnected. Remove the 20 Amp fuse from

the in-line fuse holder to power down the ECM. Do not connect or

remove the bypass connections to the battery posts without first

removing the 20 Amp in-line fuse.

Is the electronic service tool operating correctly ?

Action

The ECM is currently

receiving the correct voltage.

Go to step 6.

The ECM is not receiving the

correct voltage.

Ensure that there is not an

aftermarket engine

protection switch overriding

battery power to the ECM.

Refer to Test 40: Electrical

power supply to the ECM on

page 88.

STOP.

There is a problem in the

machine wiring.

Re-insert the two data link

lines into the ECM connector

P1.

Contact the OEM for repair.

Check that the repair

eliminates the fault.

STOP.

Check that the 20 Amp fuse

in the bypass harness of the

electronic service tool is not

open (blown).

Go to step 7.

121

![]() 4

4

2800 Series

Test 45 - Perkins Data Link circuit test (Continued)

Test step Result

Step 7: Connect the electronic service tool and ECM to another battery

Warnings!

Batteries give off flammable fumes which can explode. Do not

strike a match, cause a spark, or smoke in the vicinity of a

battery during the test procedure.

Do not connect the electronic service tool bypass harness to

the battery until the 20 Amp in-line fuse has been removed from

the +Battery line. If the fuse is not removed before connection

to the battery a spark may result.

Connect the battery wires from the bypass harness of the

electronic service tool to a different battery not on the engine.

Refer to "Service tool bypass harness schematic" on page 125.

Does the electronic service tool operate correctly ?

Action

Refer to Test 40: Electrical

power supply to the ECM on

page 88.

STOP.

Temporarily connect a test

ECM. Repeat the test step.

If the problem is corrected

with the test ECM, and

returns when the old ECM is

connected, renew the ECM.

Check that the repair

eliminates the fault.

STOP.

122

![]() 2800 Series

2800 Series

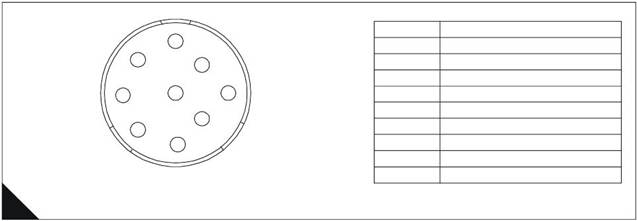

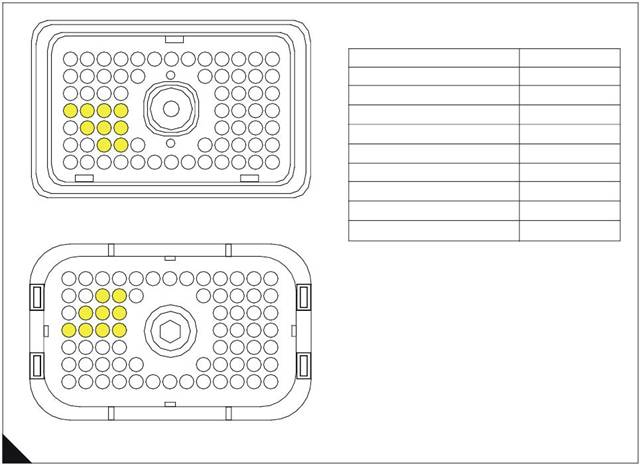

Pin allocation for communications connector

4

F

E

G

D

A

H

C

J

B

Pin No.

A

B

C

D

E

F

G

H

J

Description

Battery +

Battery -

CAN Bus Screen

Perkins Data Link +

Perkins Data Link -

J1939 CAN -

J1939 CAN +

J1922 Bus +

J1922 Bus -

B

Deutsch 9 Pin Perkins Data Link Connector

HA0027

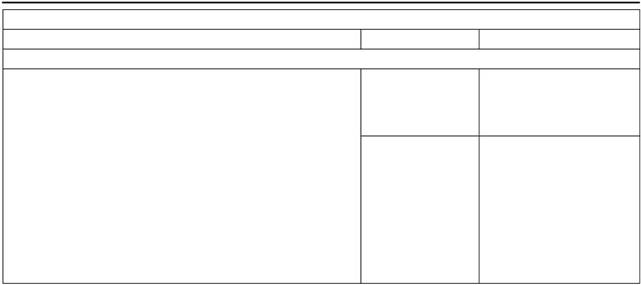

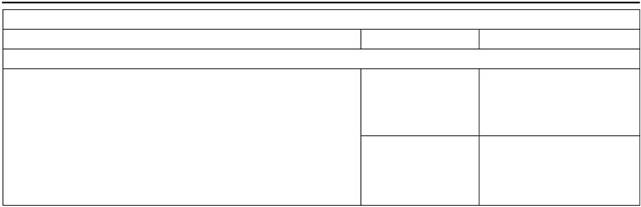

ECM terminal connections

Note: Using ECM connector P1.

13

23

31

12

22

30

11

21

29

10

20

28

9

19

8

7

6

5

18

4

17

27

3

16

26

2

15

25

1

14

24

Function

Perkins Data Link +

Perkins Data Link -

Pin Location

8

9

39

47

57

38

46

56

37 36

45 44

55 54 53

52

35

43

51

34

42

50

33 32

41 40

49 48

70

69

68

67 66

65

64

63

62 61

60

59 58

Terminal side

57

47

31

70

69

68

67 66

36

65

64

63

62 61

60

59 58

48

40

24

23

13

12

11

10

9

>PEI<

8 7

6

5

4

3

2

1

14

C

Wire side

HA0026

123

![]() 4

4

Breakout connector

Note: Using ECM connector P1.

2800 Series

13

12

11

10

9

8

7

6

5

4

3

2

1

Function

Pin Location

23

22

21 20

19

18

17

16

15

14

Unswitched Battery +

52

31

39

47

57

70

30

38

46

56

69

29 28

37 36

45 44

55 54

68 67

53

66

65

64

63

52

62

27 26

35 34

43 42

51 50

61 60

25 24

33 32

41 40

49 48

59 58

Unswitched Battery +

Key switch

Battery -

Battery -

53

70

67

65

Terminal side

57

47

31

23

70

69

68

67

66

36

65

64

63

62

61

60

59

58

48

40

24

14

13

12

11

10

9

>PEI<

8 7

6

5

4

3

2

1

D

Wire side

HA0028

124

![]() 2800 Series

2800 Series

Service tool bypass harness schematic

4

Red

Black

20 Amp

In line Fuse

J1/70

Key Switch

ECM

Unswitched Battery +

Battery -

Perkins Data Link +

Perkins Data Link -

J1922 Data Link -

J1922 Data Link +

J1939 Data Link +

J1939 Data Link -

J1939 Data Link Screen

A

B

D

E

J

H

G

F

C

9 Pin

J1/52

J1/53

J1/65

J1/67

J1/8

J1/9

J1/1

J1/14

J1/34

J1/50

J1/42

J1

Unswitched Battery +

Unswitched Battery +

Battery -

Battery -

Perkins Data Link +

Perkins Data Link -

J1922 Data Link -

J1922 Data Link +

J1939 Data Link +

J1939 Data Link -

J1939 Data Link Screen

Perkins Data Link

Connector

E

HA0029

125

![]()

![]()

![]()

![]() 4

4

2800 Series

Engine speed/timing circuit test

Test 46

Diagnostic codes

System operation

Functional test

Use this procedure to diagnose the system only when there is an active or easily repeated diagnostic code that

is associated with either the crankshaft or camshaft position sensor circuit or if you have been referred to this

test from a diagnostic procedure without a diagnostic fault code.

The engine uses two engine speed/timing sensors. One sensor picks up the camshaft gear and the other the

crankshaft gear. Both detect engine speed and timing reference from a unique pattern on the gear. The ECM

counts the time between pulses created by the sensor as the gear rotates in order to determine rev/min.

Under normal operation, the camshaft position sensor is used to determine timing (when the piston in cylinder

number 1 is at the top of the compression stroke) for starting purposes. When the timing has been established,

the crankshaft position sensor is then used to determine engine speed and the camshaft position sensor signal

is ignored.

After locating No. 1 cylinder, the ECM triggers each injector in the correct firing order and at the correct time.

The actual timing and duration of each injection is based on engine rev/min and load. If the engine is running

and the signal from the crankshaft position sensor is lost, a slight change in engine performance will be noticed

when the ECM switches to the camshaft position sensor.

Loss of the camshaft position sensor signal during engine operation will not result in any noticeable change in

engine performance. However, if the camshaft position sensor signal is not present during start-up the engine

may take slightly longer to start, or may run rough for a few seconds until the ECM determines the correct firing

order by using the crankshaft position sensor only.

The engine will start and run when only one sensor signal is present from either of the sensors. The loss of the

signal from both sensors will result in the ECM terminating injection and shutting down the engine, or

preventing it from starting.

Both sensors are magnetic with a connector on a "flying lead’.

Caution: The two sensors are not interchangeable, do not switch sensor positions.

If the sensors are replaced a timing calibration is NOT necessary for the engine.

Note: Timing calibration is only necessary after replacing an ECM that will not communicate.

If the ECM is replaced, it will be necess ary to do a Timing Calibration.

The crankshaft position sensor is connected to the ECM through the engine harness connector J2/P2 terminal-

48 (CRANK SPEED/TIMING POSITIVE) and terminal-49 (CRANK SPEED/TIMING NEGATIVE).

The camshaft position sensor is connected to the ECM through engine harness connector J2/P2 terminal-58

(CAM SPEED/TIMING POSITIVE) and terminal-59 (CAM SPEED/TIMING NEGATIVE).

126

![]() 2800 Series

2800 Series

When installing the sensors

Lubricate the O-ring with oil.

Ensure that the sensor has a connector face seal inside the connector body. If a seal is damaged or

missing, replace the seal.

Ensure that the sensor is fully seated into the engine before tightening the bracket bolt.

Ensure that the connector is latched on both sides.

Ensure that the harness is correctly secured and the tie-wraps are placed in the correct location.

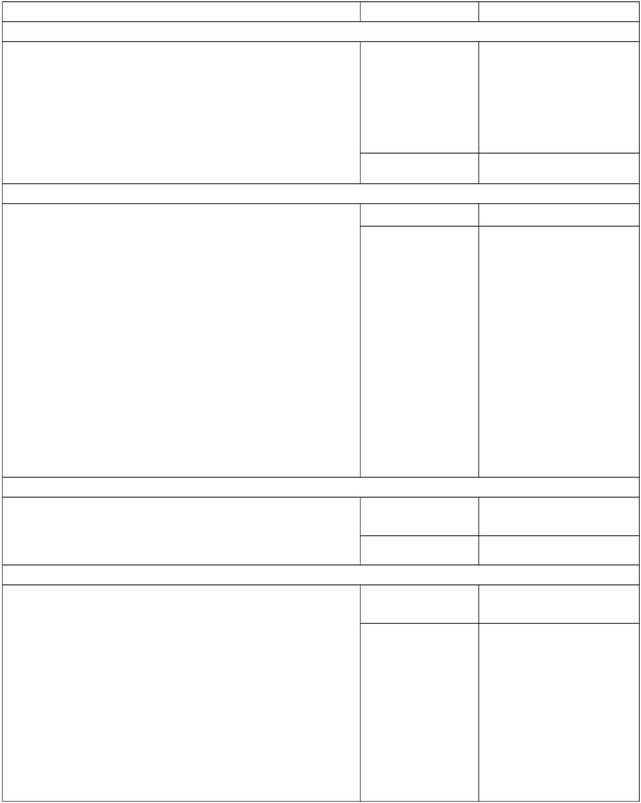

Speed/timing sensors schematic

Note: Refer to the wiring diagrams for full connection details.

4

A

|

|

Return 1

J401 P401

Camshaft Position Sensor

Return 1

J402 P402

J2/48

J2/49

J2/58

J2/59

P2 J2

ECM

Crank Speed Timing +

Crank Speed Timing -

Cam Speed timing +

Cam speed timing -

HA0030

127

|

Diagnostic codes

2800 Series

Engine response

128

![]() 2800 Series

2800 Series

Functional test

4

Test 46 - Engine speed/timing circuit test

Test step Result

Step 1: Connect an electronic service tool and note all active and logged diagnostic codes

Action

Connect the electronic service tool to the data link connector.

Turn the key switch ON, engine OFF.

Check for one of the following logged or active diagnostic

codes:

261-13 Camshaft Sensor To Crank Sensor Calibration

342-12 Loss Of Engine Cam Sensor rev/min Signal

190-12 Loss Of Engine Crank Sensor rev/min Signal

Notes:

If the diagnostic code is logged but not active, run the engine

until it is at normal operating temperature. The problem may

only occur when the engine is at the normal operating

temperature. If the engine will not start monitor the engine rev/

min from the electronic service tool while cranking the engine.

The electronic service tool may need to be powered from

another battery while cranking the engine to ensure that the

electronic service tool does not reset.

If there are occurrences of the 342-12 and 190-12 faults refer

to Test 39: Inspecting electrical connectors on page 82.

If you have been referred here from a diagnostic procedure

without a diagnostic fault code because engine rev/min was

not indicated on an electronic service tool select NO ENGINE

REV/MIN.

Are any of the diagnostic codes listed above logged or

active ?

Step 2: Check Sensors and Bracket Installation

Note: To ensure correct operation the sensor flange should be

flush against the engine.

Inspect the bracket to ensure that the installation allows the

sensor flange to be flush against the engine. Check that the

bracket is not bent. Refer to "Speed/timing sensors schematic"

on page 127. The bracket cannot be replaced separately.

Ensure that one O-ring has been installed on the sensor, and

that it is free of damage.

If a 261-13 Camshaft Sensor To Crank Sensor Calibration

diagnostic code is active, there may be a problem with the

assembly of the engine.

Are the sensors and the bracket are correctly installed ?

342-12, 190-12 or

261-13

NO CODE

NO ENGINE REV/

MIN

There is an active or logged

diagnostic code.

Go to step 3.

If none of the codes listed

are active or logged and the

engine is not running

correctly, refer to the

appropriate symptoms in

"Diagnostic procedures

without a diagnostic fault

code" on page 36.

STOP.

Engine rev/min is not

indicated on an electronic

service tool.

Go to step 2.

The sensors and the bracket

are correctly installed.

Go to step 3.

Loosen the bolt holding the

sensor bracket to the

engine.

Seat the sensor and tighten

the bolt. If the sensor will not

seat, repair or replace the

sensor as necessary. The

sensor must not be removed

from the bracket.

Ensure that the sensor is

correctly oriented and the

harness is secured in the

correct location.

STOP.

129

![]() 4

4

2800 Series

Test 46 - Engine speed/timing circuit test (Continued)

Test step Result

Step 3: Measure the sensor resistance through the engine harness

Turn the key switch OFF, engine OFF.

Thoroughly inspect ECM engine harness connector J2/P2.

Refer to Test 39: Inspecting electrical connectors on page 82.

Perform a 45 N (10 lb) pull test on ECM engine harness

connector P2 terminals-48, 49, 58 and 59. Refer to "ECM

terminal connections" on page 132.

Ensure that connector latching tab is correctly latched and is in

the fully latched position.

Check that the ECM connector All en screw is correctly

tightened to not more than 3,0 Nm (2.2 l b ft) 0,31 kgf m.

Repair the harness or connector if a problem is found.

Ensure that the wiring harness is correctly routed and secured

at the correct locations.

Note: Ensure that the wiring harness is not pulled too tight causing

intermittent connections when vibration or movement occurs.

Inspect the sensor harness wiring for cuts and abrasions.

If the harness and the connector are OK, disconnect engine

harness ECM connector J2/P2.

Use a multimeter to measure the sensor resistance (Ohms)

from engine harness connector P2 as indicated below. Move

the harness (pull/shake the wires, especially directly behind the

sensors) while taki ng a measurement to check for an

intermittent open or short circuit. Refer to "ECM terminal

connections" on page 132.

Crankshaft position sensor - The resistance from P2 terminal-48

(CRANK SPEED/TIMING POSITIVE) and terminal-49 (CRANK

SPEED/TIMING NEGATIVE) is between 75.0 and 230.0 Ohms.

Camshaft position sensor - The resistance from P2 terminal-58

(CAM SPEED/TIMING POSITIVE) and terminal-59 (CAM SPEED/

TIMING NEGATIVE) is between 600 and 1800 Ohms.

Do the readings agree with the values listed above ?

Action

The engine harness and

sensor do not indicate a

short or open circuit.

Go to step 5.

The sensor resistance is not

within the acceptable range

when measured through the

engine harness.

Go to step 4.

130

![]() 2800 Series

2800 Series

4

Test 46 - Engine speed/timing circuit test (Continued)

Test step Result

Step 4: Measure sensor resistance at the sensor

Turn the key switch OFF, engine OFF.

Check the harness and wiring for abrasion and pinch points

from the sensor back to the ECM.

Disconnect the suspect sensor from the engine harness as

described below.

Thoroughly inspect ECM engine harness sensor connector

J401/P401 or J402/P402. Refer to Test 39: Inspecting

electrical connectors on page 82 for details.

Use a multimeter to measure the sensor resistance (Ohms) at

the sensor connector between terminal-A and terminal-B.

Crankshaft position sensor - The resistance from J401 terminal-

2 (CRANK SPEED/TIMING POSITIVE) and J401 terminal-1

(CRANK SPEED/TIMING NEGATIVE) is between 75.0 and 230.0

Ohms.

Camshaft position sensor - The resistance from J402 terminal-2

(CAM SPEED/TIMING POSITIVE) and J402 terminal-1 (CAM

SPEED/TIMING NEGATIVE) is between 600 and 1800 Ohms.

Note: Timi ng calibration is not necessary fol lowing replacement of

the Crankshaft Position or camshaft position sensor. Refer to

"When installing the sensors" on page 127.

Do the readings agree with the values that are listed above ?

Step 5: Install engine speed/timing bypass harness

Ensure the key switch is OFF, engine OFF.

Disconnect engine harness ECM connector J2/P2 (if not

already disconnected).

For the crankshaft position sensor - install 16 AWG

wires from J2/P2 terminal-48 to P401 terminal-2 and from

J2/P2 terminal-49 to P401 terminal-1.

For the camshaft position sensor - install 16 AWG wires

from J2/P2 terminal-58 to P402 terminal-2 and from J2/P2

terminal-59 to P402 terminal-1.

Reconnect the engine harness connector J2/P2.

Start the engine to determine if the bypass harness repairs the

problem.

Is the problem corrected with the bypass installed ?

Action

The sensor resistance i s

correct.

Go to step 5.

The sensor resistance is out

of range, obtain a new

sensor.

Before installing the new

sensor, measure the

resistance of the new sensor

as outlined in the test step

using the same test setup

(test harness, multimeter

and meter settings). If the

new sensor is in range,

install the new sensor in the

engine.

Loosen the bolt holding the

sensor bracket to the

engine. Ensure the O-ring is

installed and free of

damage. Seat the sensor

and tighten the bol t.

If the sensor will not seat,

repair or replace the sensor,

as necessary.

The sensor must not be

removed from the bracket.

Ensure that the sensor is

correctly oriented and the

harness is secured in the

correct location.

STOP.

Permanently install a new

harness section.

STOP.

Double check to ensure that

the correct terminals have

been installed in the correct

location of the ECM engine

harness connector P2.

If the temporary harness

was installed correctly,

install the original wiring.

Go to step 6.

131

![]() 4

4

2800 Series

Step 6: Check the ECM

Test 46 - Engine speed/timing circuit test (Continued)

Test step Result

Action

Turn the key switch OFF, engine OFF.

Temporarily connect a test ECM.

Start the engine and run it to repeat the conditions when the

problem occurs. Determine if the problem is corrected with the

test ECM.

If the problem does not return with the test ECM, reinstall the

suspect ECM and ensure that the problem returns.

Does the problem remain with the suspect ECM ?

If the test ECM works and

the suspect ECM does not,

replace the ECM.

STOP.

Replace the sensor and

ensure that the problem is

corrected.

STOP.

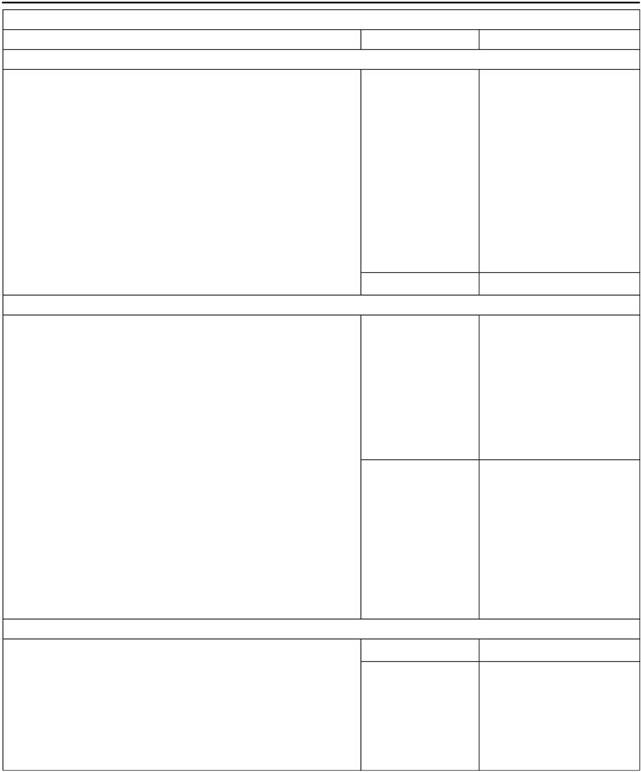

ECM terminal connections

Note: Using ECM connector P2.

13

12

11

10

9

8

7

6

5

4

3

2

1

Function

Pin Location

23

22

21

20 19

18

17

16

15

14

Crank Speed/Timing Signal +

48

31

30

29 28

27

26

25

24

Crank Speed/Timing Signal -

49

39

47

38

46

37 36

45 44

35 34

43 42

50

33

41

49

32

40

48

Cam Speed/Timing Signal +

Cam Speed/Timing Signal -

58

59

57

56 55

54

53

52

51

70 69

68

67

66

65 64 63

62

61

60 59

58

Terminal side

57

47

31

70 69

68

67

66

36

65

64 63

62

61

60 59

58

48

40

24

23

13

12

11

10

9

>PEI<

8 7

6

5

4

3

2

1

14

B

Wire side

HA0031

132

![]() 2800 Series

2800 Series

Speed and timing sensors

1 Crankshaft speed and timing s ensor

2 Mounting bracket

3 Cable connection

Note: This is not a connector. Do not try to disassemble.

4 Connector

5 Camshaft speed and timing sensor

4

3

2

1

3

2

5

4

4

C

HA0032

133

![]()

![]()

![]()

![]() 4

4

2800 Series

Engine speed/timing calibration

Test 47

Diagnostic codes

Special tools

Functional test

|

Part Number |

Description |

|

GE50038 |

Timing calibration probe |

|

GE50040 |

Harness adapter for deutsch “DT” timing probe connection |

|

GE50039 |

Timing calibration probe adapter sleeve |

|

CH11148 |

Engine turning tool |

System operation

Use this procedure if diagnostic code 261-13 Check Timing Sensor Calibration is present, if the ECM has been

replaced or if work has been done to the engine front drive train.

The crankshaft position sensor provides an engine speed signal (rev/min) to the ECM. The signal is created

as the crankshaft gear rotates past the pickup of the crankshaft position sensor. The camshaft position sensor

provides the timing signal to the ECM. The signal is created as the camshaft gear rotates past the pickup of

the camshaft position sensor. A unique pattern on the gear allows the ECM to determine the crankshaft

position and when the cylinder number one piston is at the top of the compression stroke. In the event that the

signal is lost from one of the sensors, a diagnostic code is generated. The ECM then uses special logic to allow

the engine to start and run on only one sensor.

If the ECM requires replacement or if work has been performed on the front drive train, a timing calibration

mus t be performed.

Timing calibration is accomplished by installing a special magnetic pickup into the side of the engine block.

The magnetic pickup senses a spec ial slot on the crankshaft counterweight. The magnetic pickup is then

connected to the ECM through the engine harness speed/timing calibration connector P400, while the engine

is running.

In order to carry out a timing calibration, the engine must be running at 1100 rev/min. Since this speed is not

within the range of the normal speed setting controls, proceed as follows:

1 Set the "Digital Speed Control Installed" to "Not Installed" from the TIPSS-EST configuration screen.

2 If an analogue speed control is fitted, select PWM speed control in the "Desired Speed Input Arrangement"

option on the configuration screen. If a PWM speed control is fitted, select Analogue speed control in the

"Desired Speed Input Arrangement" on the configuration screen.

Note: If both analogue and PWM speed inputs are connected, one must be disconnected and the associated

speed control selected.

3 If the engine is now run, it should run up to 1100 rev/min and timing calibration can be carried out.

4 After completion of the timing calibration, ensure that all parameters are returned to their original values.

Note: Timing calibration will not increase or decrease the available engine power. Do not c alibrate the engine

timing expecting an increase in engine power.

134

![]() 2800 Series

2800 Series

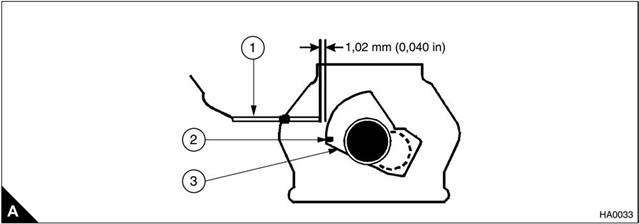

Timing calibration

1 GE50038 TC probe

2 Slot

3 Counterweight

4

Diagnostic codes

|

Diagnostic fault code |

Conditions that could cause the code |

System response |

To find the fault |

|

261-13 |

Check Timing Sensor Calibration Timing has not been calibrated since the ECM was installed or the calibration is out of specification more than the ECM will allow. |

Electronic system response The ECM uses default timing. Timing can be out of specification by as much as 4°. Engine response The engine may run rough, emit white smoke in the exhaust or there may not be any noticeable performance effect. |

Proceed with Test 47: Engine speed/ timing calibration. |

135

4

4

Functional test

2800 Series

Test 47 - Engine speed/timing calibration

Test step Result

Step 1: Install the timing adapter group

Turn the key switch OFF, engine OFF

Use the turni ng tool to put either the No. 1 or No. 6 piston at top

centre. After locating top centre, rotate the engine back (rotate

the engine in opposite direction of correct engine rotation) 60°.

Remove the timing calibration plug from the left side of the

engine and install the timing probe adapter sleeve into the hol e

for the plug.

Step 2: Install GE50038 TC probe on the engine

Caution: If the crankshaft is not in the correct position when the

timing probe is installed, the timing probe will be damaged when

the engine is started.

Put a 2D-6392 O-ring on the end of the magnetic pickup sensor

(a small amount of clean engine oil wil l allow the seal to slide

onto the sensor more easily).

Push the sensor through the adapter until it comes in contact

with the outermost portion of the crankshaft counterweight.

Move the O-ring downward against the adapter.

Withdraw the magnetic transducer 1,0 mm (0.04 in) and hand

tighten the nut on the adapter sleeve in order to secure the

magnetic pickup in place.

Connect the GE50038 timing probe to the GE50040 Deutsch

DT timing harness adapter.

Step 3: Start engine and allow coolant to reach operating temperature

Start the engine and run until the engine has warmed up

enough to exit cold mode operation. The electronic service tool

"Status" screen will display “COLD MODE” in the upper corner

when cold mode operation exists.

Check for ACTIVE diagnostic codes. Use the procedures in this

manual to diagnose and repair any ACTIVE diagnostic codes

before attempting a calibration check. The engine must not

have any diagnostic fault conditions present during the timing

calibration, other than 261-13 Check Timing Sensor

Calibration.

Stop the engine.

Step 4: Connect an electronic service tool

Connect an electronic service tool to the data link connector.

Follow the procedure in "System operation" on page 134 so

that the engine will run at 1100 rev/min.

Access the "Timing Calibration" screen located under the

"Service\Calibrations" menu on TIPSS-EST.

Note: To perform a timing calibration, the engine rev/min must be

held as steady as possible at approximately 1100 rev/min. Any

changes to engine rev/min (greater than 100 rev/min) will slow

down the procedure and reduce accuracy. The correct engine

speed is set using the procedure described "System operation" on

page 134.

Connect the GE50040 Deutsch DT adapter harness for the

GE50038 timing probe to the speed/timing calibration

connector P400.

Be certain that all connections (TC Probe, electronic service

tool, etc) are made correctly.

Start the engine

Action

Go to step 2.

Go to step 3.

Go to step 4.

Go to step 5.

136

![]() 2800 Series

2800 Series

4

Test 47 - Engine speed/timing calibration (Continued)

Test step Result

Step 5: Calibrate the speed/timing sensor

To calibrate the timing to the correct setting select Continue on

the electronic service tool and wait until the electronic service

tool indicates that the timing is CALIBRATED.

Note: If the electronic service tool display reads CALIBRATION

UNSUCCESSFUL, the electronic injection timing has not been set.

Re-check the tool installation and tool operation and try again

to calibrate electronic injection timing. If the crankshaft and

camshaft gears have been reassembled incorrectly (relative to

each other), the engine will not calibrate.

If the timing calibration has been successfully completed, do

not exit the Timing Calibration Screen on the electronic service

tool until you have disconnected the timing probe from the

speed/timing calibration connector P400.

Was the timing calibration procedure completed

successfully ?

Action

The timing calibration

procedure was completed

successfully.

Go to step 6.

Check that the engine rev/

min was stable during the

testing (+/- 50 rev/min).

If the engine rev/min was

unstable or could not be

controlled within +/- 50 rev/

min because of mechanical

or electrical factors, refer to

Test 3: Engine misfires, runs

rough or is unstable on page

39.

If all of the checks are OK

but the timing still will not

calibrate, check the timing

probe cable and timing

probe to ensure it is not bent.

If it is not bent, restart this

procedure.

|

|

|

|

Disconnect the timing probe from the speed/timing calibration Go to step 7.

Exit the electronic service tool "Timing Calibration" screen. installed following exit of the

electronic service tool

Timing Calibration Screen,

engine speed diagnostic

codes may be generated

and should be cleared.

STOP.

Step 7: Restore correct engine speed

Use TIPSS-EST to restore the correct digital, analogue or STOP.

Run the engine to check the correct running speed. selection.

137

![]()

![]()

![]()

![]() 4

4

2800 Series

Injector solenoids circuit test

Test 48

Diagnostic codes

System operation

Functional test

Use this procedure if a 1-11, 2-11, 3-11, 4-11, 5-11, 6-11 Cylinder Fault is present or is you have been referred

here after following the sequence of steps in Test 3: Engine misfires, runs rough or is unstable on page 39, or

Test 4: Low power/poor or no response to throttle on page 40.

It is important to perform this procedure when the injector is under identical conditions as when the problem

occurs. Typically, injector solenoid problems occur when the engine is warmed up and/or when the engine is

under vibration (heavy loads).

The 2300 and 2800 Series engines utilize electronic unit injectors that are mechanically actuated and

electronically energized.

The injectors can be individually cut out while the engine is running to check for weak cylinders, or tested

without the engine running to check for electrical circuit problems.

The injector solenoid is mounted on top of the fuel injector body along side the rocker arm return spring.

Injector Trim Codes provide a means to fine tune each individual injector for optimum performance. A 268-02

Check Programmable Parameters diagnostic code will be active if the injector codes are not programmed.

If the ECM is replaced, all six injector codes must be programmed into the new ECM.

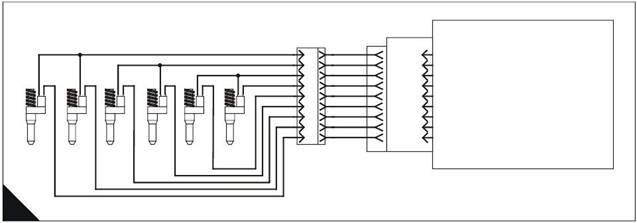

Injector schematic

Note: Refer to the wiring diagrams for full connection details.

Injector

Cyl 1

Injector

Cyl 2

Injector

Cyl 3

Injector

Cyl 4

Injector

Cyl 5

Injector

Cyl 6

|

|

6

10

3

11

12

1

J300 P300

|

J2/45

J2/46

J2/54

J2/39

J2/38

J2/37

J2/36

P2 J2

|

Injector Common Cylinders 1 & 2

Injector Common Cylinders 3 & 4

Injector Common Cylinders 5 & 6

Injector Cylinder 6

Injector Cylinder 5

Injector Cylinder 4

Injector Cylinder 3

Injector Cylinder 1

A

HA0034

138

|

Diagnostic codes

4

lamp ON and log the diagnostic

code. If the cause of the diagnostic

48: Injector

solenoids circuit

cylinders will be affected because

Functional test

Test step

Test 48 - Injector solenoids circuit test

Result

Action

Step 1: Inspect electrical connectors and wiring

Turn key switch OFF, engine OFF

Warning! Ensure that the key switch is OFF. Possible strong

electrical shock hazard if the key switch is not turned OFF.

Thoroughly inspect the ECM engine harness connector J2/P2

and the injector solenoids connector.

Perform a 45 N (10 lb) pull test on each of the wires in the ECM

connector and the injector solenoids connector.

Check that the ECM connector Allen screw is correctly

tightened to not more than 3,0 Nm (2.2 lb ft) 0,31 kgf m.

Check the injector solenoids connector to ensure that it is

correctly mated.

Check the harness and wiring for abrasion and pinch points

from the injector(s) back to the ECM.

Are connectors/pins/sockets completely mated/inserted, and

the harness/wiring free of corrosion, abrasion or pinch

points ?

Step 2: Check for logged injector solenoid diagnostic codes

Connect an electronic service tool to the data link connector.

Turn the key switch ON, engine OFF

Access the screen displaying logged diagnostic codes

Does the service tool indicate a logged 1-11, 2-11, 3-11, 4-11,

5-11 or 6-11 cylinder fault ?

Go to step 2.

Repair or replace wiring or

connectors as necessary.

Ensure all seals are correctly

installed and that connectors

are completely mated.

Check that the repair

eliminates the fault.

STOP.

Go to step 4.

Go to step 3.

139

![]() 4

4

2800 Series

Test 48 - Injector solenoids circuit test (Continued)

Test step Result

Step 3: Check cylinder to cylinder variation of injectors

Connect the TIPSS-EST to the data link connector.

Start the engine.

Allow the engine to warm up to normal operating temperature -

77 °C (171 °F).

Access the Cylinder cut-out test located under the

"Diagnostics\Diagnostic Tests" menu.

Select the start button at the bottom of the "Cylinder cut-out"

test screen.

Do all cylinders indicate OK on the TIPSS-EST screen?

Step 4: Check injector solenoids using the TIPSS-EST Injector Solenoid test

Start the engine.

Allow the engine to warm up to normal operating temperature -

77 °C (171 °F)

Turn the key switch OFF, engine OFF

Connect an electronic service tool at the data link connector.

Turn the key switch ON, engine ON

After the engine is warmed to operating temperature, access

and begin the Injector Solenoid test located under the

"Diagnostics\Diagnostic Tests" menu of the electronic service

tool.

Note: Do not confuse the Injector Solenoid test with the Cylinder

cut-out test. The Cylinder cut-out test is used to shut off fuel to a

specific cylinder while the engine is running. The Injector Solenoid

test is used in order to actuate the injector solenoids in order to

"hear" the injector solenoids click, when the engine is not running,

to determine that the circuit is functioning correctly.

Perform the Injector Solenoid test two or three times.

Do all cylinders indicate OK ?

Action

All cylinders test OK.

If a misfiring problem or low

power problem still exists

refer to Test 3: Engine

misfires, runs rough or is

unstable on page 39 or Test

4: Low power/poor or no

response to throttle on page

40.

If a diagnostic code results

from running the Cylinder

cut-out test then Go to step

4.

Go to step 4.

There is not an electronic

problem with the injectors at

this time.

If the Cylinder cut-out test

returned a NOT OK for any

injector, refer to Test 3:

Engine misfires, runs rough

or is unstable on page 39.

STOP.

Note the cylinders that

indicate OPEN and/or

SHORT.

Go to step 5.

|

Turn key switch OFF, engine OFF Go to step 7.

electrical shock hazard if the key switch is not turned OFF. indicating the short circuit.

Disconnect the injector solenoids connector J300/P300 Go to step 6.

Turn the key switch ON, engine OFF

Perform the Injector Solenoid test two or three times.

Do all cylinders indicate OPEN ?

140

![]() 2800 Series

2800 Series

4

Test 48 - Injector solenoids circuit test (Continued)

Test step Result

Step 6: Check ECM for short circuits using service tool Injector Solenoid test

Turn key switch OFF, engine OFF

Warning! Ensure that the key switch is OFF. Possible strong

electrical shock hazard if the key switch is not turned OFF.

Disconnect ECM engine harness connector J2/P2 from the

ECM and check for evidence of moisture entry.

Turn the key switch ON, engine OFF

Perform the Injector Solenoid test two or three times.

Note: With the engine harness disconnected all of the +5 V

supplied sensor open circuit diagnostic codes will be active. This is

normal. Clear all of these diagnostic codes after completing this

test step.

Do all cylinders indicate OPEN with engine harness connector

P2 disconnected from the ECM ?

Action

The short circuit is in the

engine harness.

Repair or replace the engine

harness as required.

Clear all diagnostic codes

after completing this test

step.

STOP.

Temporarily connect

another ECM.

Repeat this test step. If the

problem is resolved with the

new ECM, reconnect the old

ECM to check that the

problem returns with the old

ECM.

If the new ECM works and

the old one did not, renew

the ECM.

STOP.

|

|

|

|

|

|

|

|

|

|

|

Turn key switch OFF, engine OFF If the previous step indicated

Disconnect injector solenoids connector J300/P300. but the injector sharing the

Turn the key switch ON, engine OFF injector common indicates a

Make a jumper wire 100 mm (4 in) long with a Deutsch Pin on

both ends. Go to step 9.

Insert the jumper wire between the injector common socket of If the previous step indicated

the problem injector, and the problem injector socket of the two injectors sharing an

injector solenoids connector P300. For example, if injector 5 is injector common are open.

Perform the Injector Solenoid test two or three times. injector common are short.

Go to step 8.

Repeat this test for each suspect injector. Ensure that the

Injector Solenoid test is disabled before handling the jumper

wires.

141

![]() 4

4

2800 Series

Test 48 - Injector solenoids circuit test (Continued)

Test step Result

Step 8: Check ECM for open circuit

Turn key switch OFF, engine OFF

Warning! Ensure that the key switch is OFF. Possible strong

electrical shock hazard if the key switch is not turned OFF.

Disconnect the engine harness from the ECM connector J2

and connect a 70-terminal breakout T to the ECM (do not

connect the engine harness to the breakout T).

Use a jumper wire to short between the injector socket and the

injector common socket of the suspect injector.

Perform the Injector Solenoid test two or three times.

Note: With the engine harness disconnected all of the +5 V

supplied sensor open circuit diagnostic codes will be active. This is

normal. Clear all of these diagnostic codes after completing this

test step.

Does the cylinder with the jumper wire installed indicate

SHORT ?

Step 9: Check injector harness under valve cover

Turn key switch OFF, engine OFF

Warning! Ensure that the key switch is OFF. Possible strong

electrical shock hazard if the key switch is not turned OFF.

Remove the valve cover to gain access to the problem

injector(s).

Disconnect the harness from the problem injector and from the

other injector sharing the same inj ector common.

Thoroughly clean the terminals of both injectors and the

harness. Exchange the harness between the two injectors

sharing the common.

Turn key switch ON, engine OFF

Perform the Injector Solenoid test two or three times.

Did the problem change to the other injector with the

movement (exchanging terminals) of the harness ?

Step 10: Check engine harness under valve cover for an open circuit in the common

Turn key switch OFF, engine OFF

Warning! Ensure that the key switch is OFF. Possible strong

electrical shock hazard if the key switch is not turned OFF.

Remove the valve cover to gain access to the problem

injector(s).

Disconnect each of the injectors i ndi cating an OPEN from the

wiring harness. Ensure that each of the connectors from the

disconnected injector harness does not touch other

components and short to ground.

Attach a jumper wire to both terminals of the injector harness

for the two injectors shari ng an injector common.

Turn key switch ON, engine OFF

Perform the Injector Solenoid test two or three times.

Do both cylinders with the short in place indicate an OPEN ?

Action

The ECM is OK. Replace or

repair the engine harness.

STOP.

Temporarily connect

another ECM.

Repeat this test step. If the

problem is resolved with the

new ECM, reconnect the old

ECM to check that the

problem returns with the old

ECM.

If the new ECM works and

the old one did not, renew

the ECM.

STOP.

Replace the faulty injector

indicating the problem.

Restore the wiring to the

correct injector(s).

STOP.

Replace the injector harness

under the valve cover.

STOP.

Replace the engine harness

under the valve cover.

Check new harness

installation using the Injector

Solenoid test before

installing the valve covers.

STOP.

BOTH injectors indicate

SHORT.

Replace BOTH injectors.

STOP.

142

![]() 2800 Series

2800 Series

4

Test 48 - Injector solenoids circuit test (Continued)

Test step Result

Step 11: Check engine harness under valve cover for short circuits in the injector wires

Action

Turn key switch OFF, engine OFF

Warning! Ensure that the key switch is OFF. Possible strong

electrical shock hazard if the key switch is not turned OFF.

Remove the valve cover to gain access to the problem

injector(s).

Disconnect each of the injectors indicating an SHORT from the

wiring harness. Ensure that each of the connectors from the

disconnected injector harness does not touch other

components and short to ground.

Turn key switch ON, engine OFF

Perform the Injector Solenoid test two or three times.

Do both cylinders indicate an OPEN ?